Main Features:

1.Brand‐new industry design combined with modern aesthetic concept, high‐quality production technology, simple appearance.

2.Latest high‐frequency responding hydraulic control technology, faster, more efficient and accurate.

3.Heat treatment of the rack, rigidity optimization verification on entire machine and the application of hydraulic crowning structure jointly ensure the bending precision of MB8 series Press Brakes.

4.Optimal ratio of parameters and top‐level core configuration ensure stable performance, and easy operation.

5.MB8 standard 2 shafts back gauge system, as to complex shape work pieces ,4 or 5 shafts back gauge system and corresponding dies are available for your option.

6.Press Brake using fully closed‐loop electro‐hydraulic servo control technology, slider position signals can be feedback to NC system by bilateral gratings, then NC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider(Y1,Y2)running on the same frequency, maintaining the parallel state of the worktable.

7.According to state of sheet metal on the Press Brake, CNC system can automatically control the table deflection crowning yielding uniform length of all workpiece angles.

8.Application of hydraulic crowning gives access to uniform length workpieces . Hydraulic deflection crowning consists of a set of oil cylinders under the worktable, which can make the table occurs relative movement and form an ideal convex curve, ensuring the relative position relations with slider keep unchanged. crowning values are subject to plate thickness and properties of material to be cut.

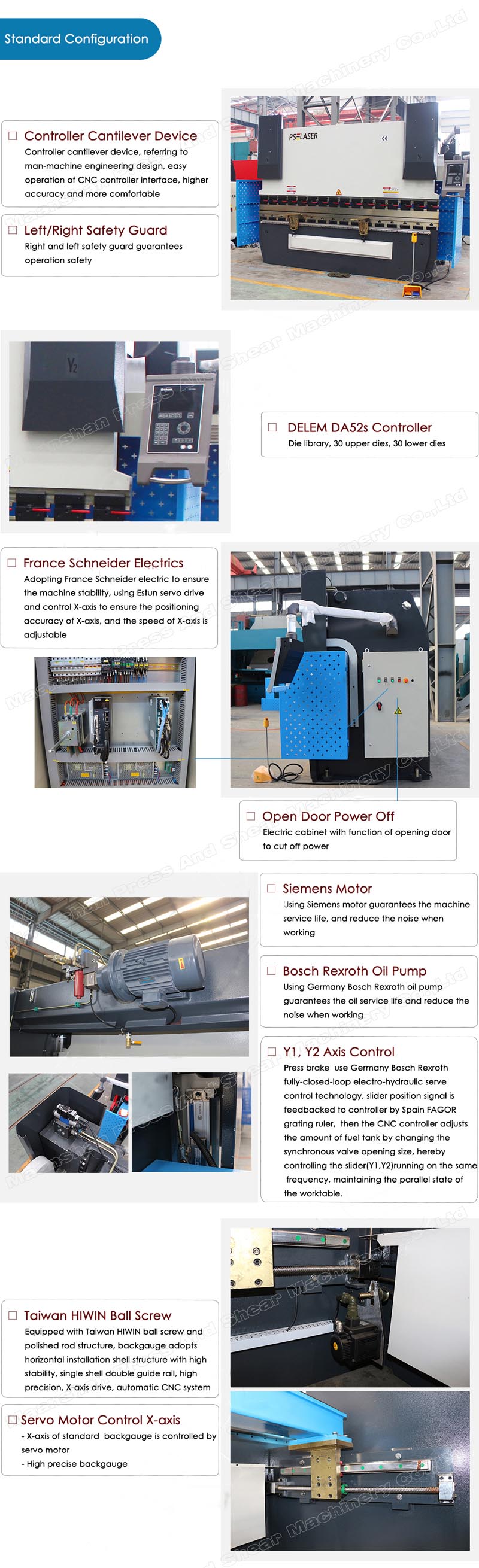

Main Configuration:

●CNC system adopts Netherlands DELEM DA52S

●Grating ruler controls depth Y1 and Y2 axis(y1/y2‐axis 0.01mm)

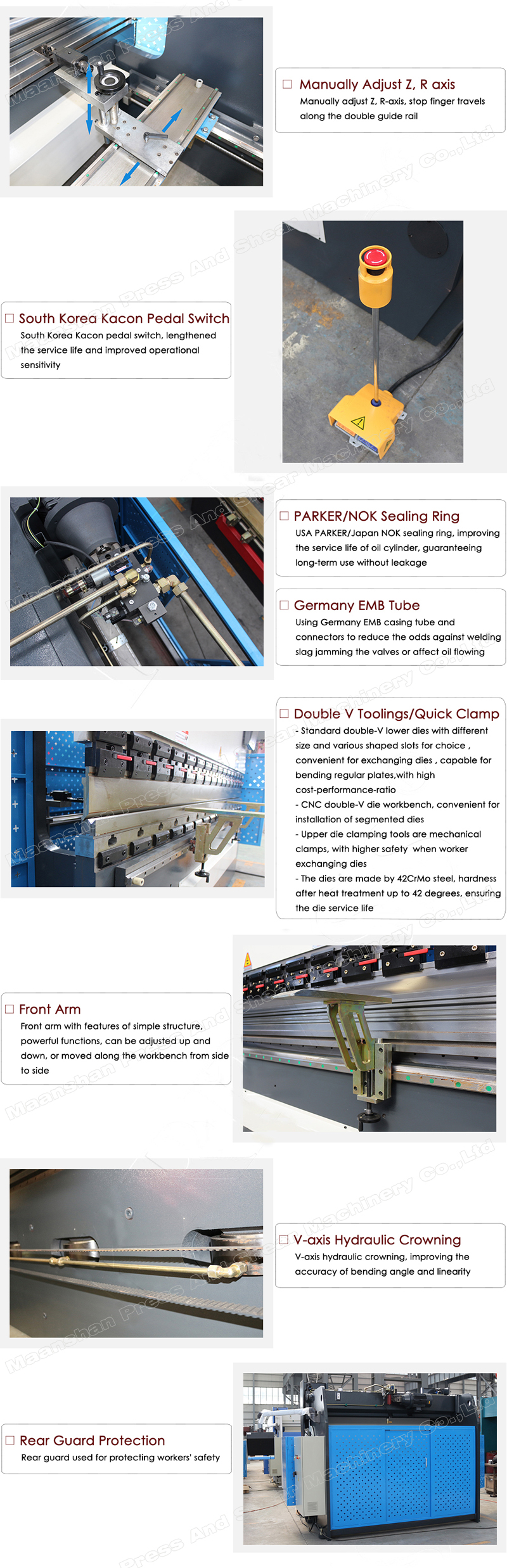

●Servo motor drive and control X axis(X‐axis 0.01mm), manually adjusts R axis up and down, fingers can easily move along the cylindrical guide.

●Keep the accuracy between HIWIN ball screw and linear guide within 0.01mm

●Front carrier can be adjusted along the linear guide in the worktable direction

●Germany Rexroth closed‐loop electro‐hydraulic servo synchronously controls the system

●Germany EMB oil tube connectors

●Germany Siemens main motor

●France Schneider Electrics

●Hydraulic and electrical overload protection

●Upper are mechanical fast pinching dies. Lower are double‐V quick changing dies

Safety Standard:

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204‐1:2006+A1:2009

●Front finger protection device ( safety light curtain )

●South Korea KACON pedal switch ( 4 security grade )

●Metal safeguard, CE standard

●Safety relay monitors completed with pedal switch, safety protection devices

●Safety standard(2006/42/EC)

Holland Delem DA52S Controller:

●8"wide‐frequency colored screen

●Max 4‐axes control (Y1, Y2, two additional axes )

●266MHZ processor, memory capacity of 64M

●Die library, 30 upper dies, 30 lower dies

●USB memory interface, RS232 interface

●Real‐time Windows operating platform to ensure the stability of the operation, support instant shutdown

●One‐page parameters for quick editing, navigation shortcuts

●Automatically calculate deflection crowning value

●Micro switch panel, data editing

●Automatically calculate the bending pressure and die safety regio

●Online operation analysis tool, Diagnostic Dashboard, angle calibration database

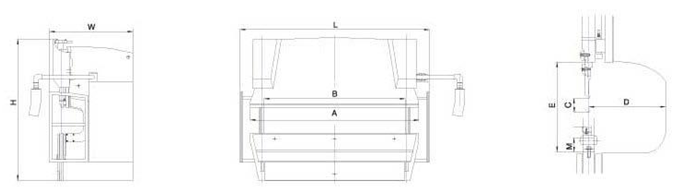

Technical Parameters:

| Models |

Nomal

Pressure

(Kn)

|

Length

of Table

(mm)

|

Distance Between

Housing (mm)

|

Throat

Depth

(mm)

|

Stroke

(mm)

|

Open Hight

(mm)

|

Main Motor

(Kw)

|

Weight (t) |

Overall

Dimensions

(L*W*H) (mm)

|

| 63/2500 | 630 | 2500 | 2000 | 320 | 150 | 380 | 5.5 | 5 | 2875*1650*2350 |

| 63/3200 | 630 | 3200 | 2700 | 320 | 150 | 380 | 5.5 | 5.5 | 3800*1650*2450 |

| 100/3200 | 1000 | 3200 | 2700 | 400 | 180 | 440 | 7.5 | 7.5 | 3810*1750*2530 |

| 125/3200 | 1250 | 3200 | 2700 | 400 | 180 | 440 | 7.5 | 8.2 | 3820*1800*2530 |

| 125/4000 | 1250 | 4000 | 3200 | 400 | 180 | 440 | 7.5 | 9 | 4600*1800*2580 |

| 160/3200 | 1600 | 3200 | 2700 | 400 | 180 | 450 | 11 | 10.8 | 3830*1870*2560 |

| 160/4000 | 1600 | 4000 | 3200 | 400 | 180 | 450 | 11 | 11.5 | 4610*1920*2700 |

| 200/3200 | 2000 | 3200 | 2700 | 400 | 180 | 450 | 11 | 12.5 | 3900*1920*2560 |

| 200/4000 | 2000 | 4000 | 3200 | 400 | 180 | 450 | 11 | 13.8 | 4620*1950*2700 |

| 200/6000 | 2000 | 6000 | 4800 | 400 | 180 | 480 | 11 | 18.5 | 6080*1950*2900 |

| 250/3200 | 2500 | 3200 | 2700 | 400 | 200 | 480 | 15 | 15 | 3900*2150*2950 |

| 250/4000 | 2500 | 4000 | 3200 | 400 | 200 | 480 | 15 | 16.5 | 4080*2150*3000 |

| 250/5000 | 2500 | 5000 | 4000 | 400 | 250 | 560 | 15 | 17.5 | 5080*2200*3250 |

| 250/6000 | 2500 | 6000 | 4800 | 400 | 250 | 560 | 15 | 20 | 6080*2200*3400 |

| 300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 560 | 22 | 19 | 4080*2200*3200 |

| 300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 560 | 22 | 21 | 5100*2200*3300 |

Contact: Mark Tsai

Phone: 0086 18156882778

Tel: 0086 555 8222125

Email: info@pressandshear.cn

Add: 4-602, Ivalley Maanshan Park, Maanshan ,Anhui,China