Advantages:

-

Acceleration speed: 19.6m/s2(2G)

-

Maximum simultaneous positioning speed: 160m/min.

-

Precision:±0.05mm.

-

Energy efficiency: Greatly reduces the power consumption.

-

Excellent cutting quality for metal sheets of small thickness and medium thickness

-

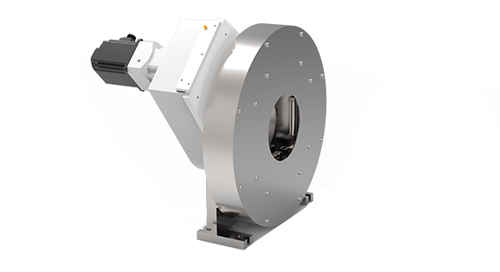

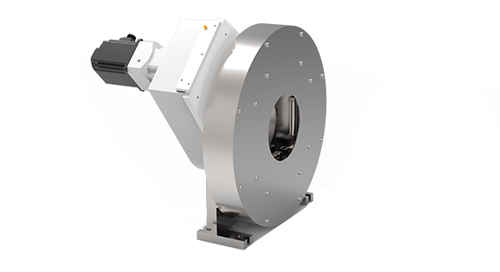

IPG Resonator. Power output from 1KW to 6KW.

-

Precitec cutting head with power output of 3KW

-

Precitec HP cuting head for power output over 3kW

-

Fully enclosed and cabined to protect the operator to the greatest extent possible.

-

Effective high and low pressure gases exchange system

-

Capacitive sensor, high pressure cutting head.

-

ECO cutting parameter table.

-

Pre-cut film protector.

-

Automatic mechanical nesting power output control function (edges, start-ups)

-

Automatic time and unit cost calculation function.

-

Network connection form external.

-

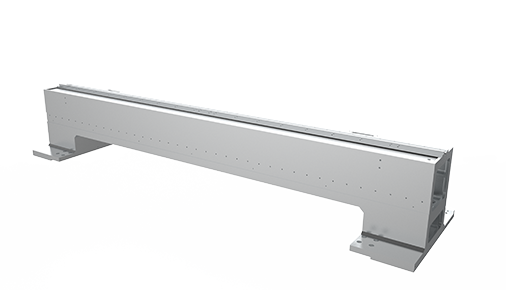

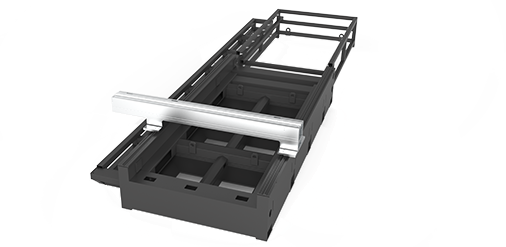

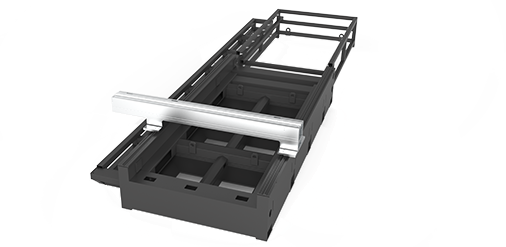

Automatic table exchanger (included in the models of this series)

-

Smoke extraction (included in the models of this series).

-

3-point reference sensor (sheet metal rotation detector)

-

Piercing sensor. Collection of work pieces and trimmings

-

Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

The laser head can change the laser beam focus automatically by setting the parameters to cut plates with different thickness or punch a hole efficiently, and the double water-cooling device has been installed in the laser head to protect the lens form overheating, which can keep the accuracy of focus and make the working life longer.

The double chucks were used to grasp the tube, the square tube and other kinds of tubes.

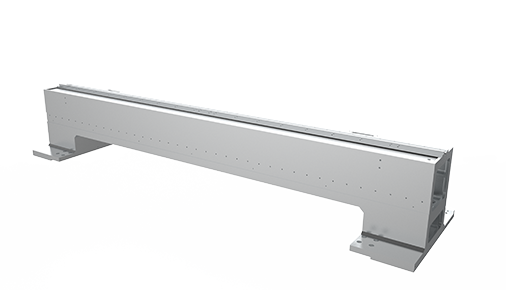

The welding process of the fiber laser cutter is followed by high-temperature tempering, which can reduce the stress of welding and processing and decrease machining error caused by machine vibration.

Cutting Samples

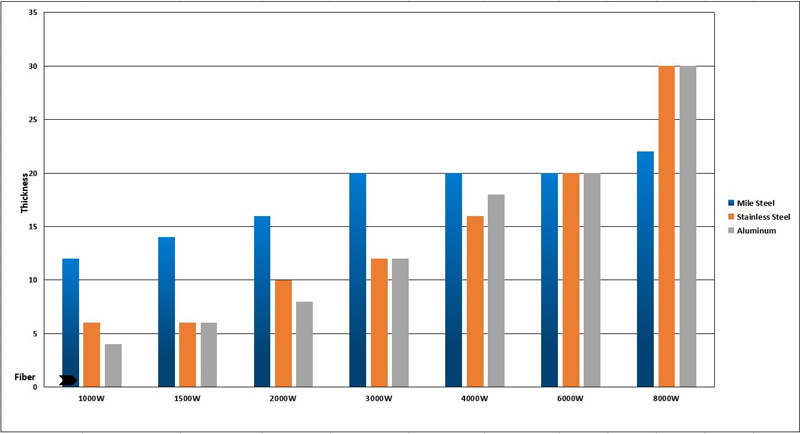

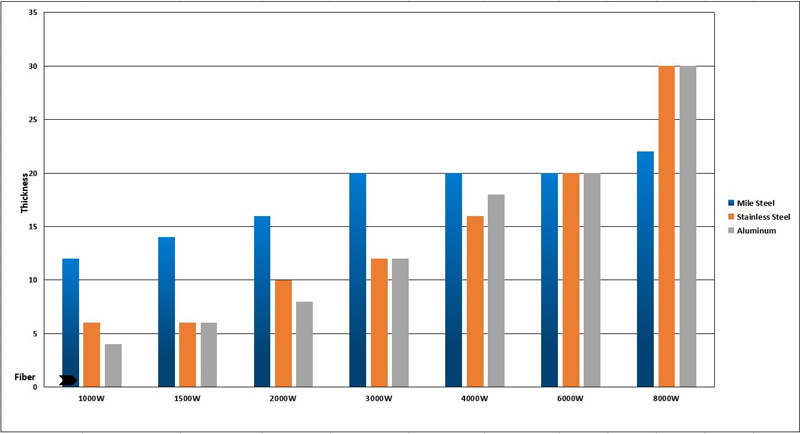

Cutting Thickness